What is EPS?

Expanded Polystyrene (EPS) foam is a lightweight and durable material widely used in the packaging and insulation industries. However, because it decomposes very slowly in nature, it can lead to significant environmental issues. EPS foam melting machines offer a solution by recycling this waste, benefiting both the environment and the economy.

What is an EPS Foam Melting Machine?

EPS foam melting machines are devices that reduce the volume of waste foam by up to 90% through a heating process, transforming it into compact, manageable blocks. This significantly simplifies transportation and storage while contributing to the recycling process.

How Does an EPS Foam Melting Machine Work?

-

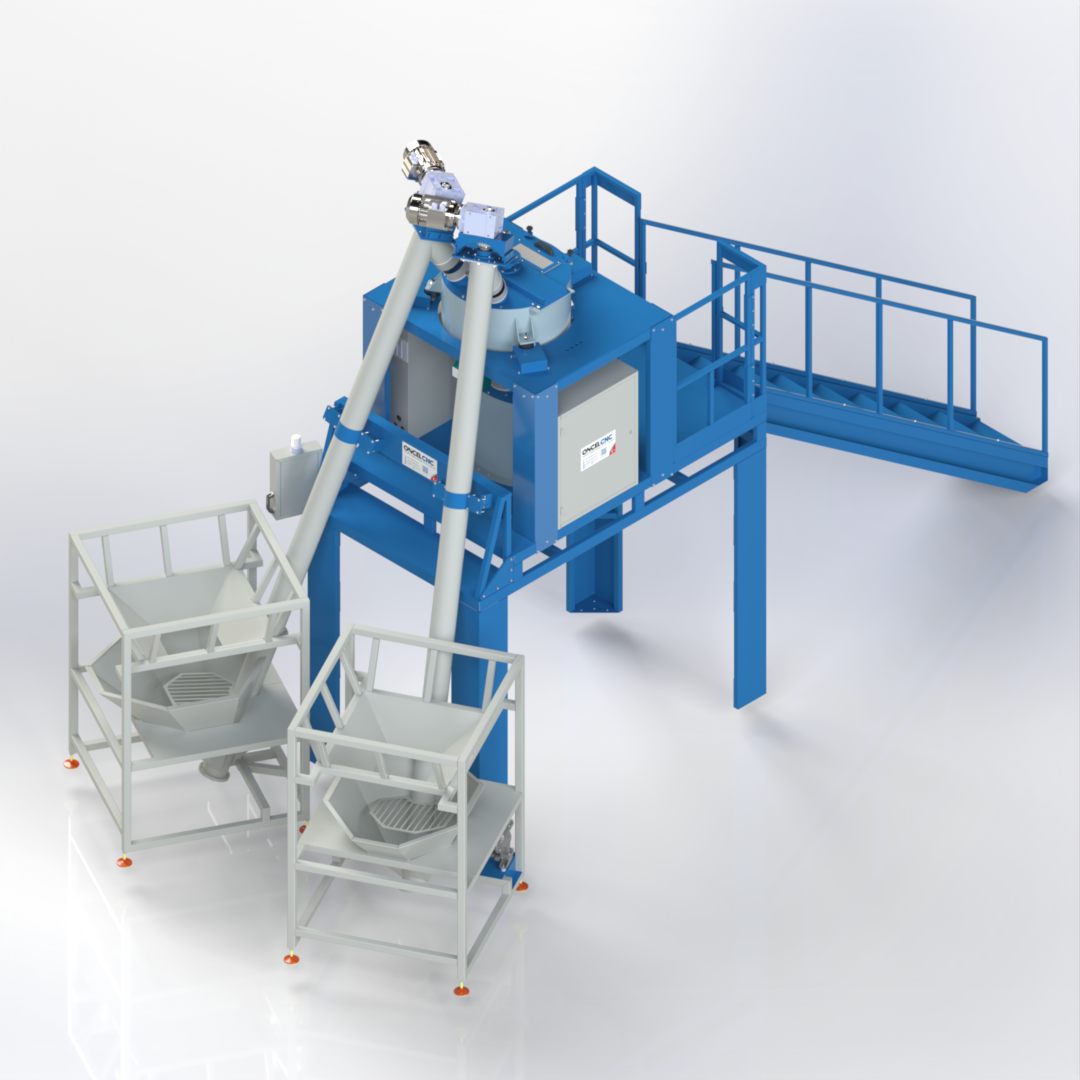

Feeding and Crushing: Waste EPS foam is fed into the machine either manually or automatically. Inside, a dual-shaft shredder breaks the foam into smaller pieces.

-

Heating and Melting: The crushed foam is transferred to a heated barrel. A rotating screw mechanism melts the foam, significantly reducing its volume.

-

Extrusion: The melted foam is discharged as dense, solid blocks, which are easy to store and transport.

-

Temperature Control: The machine operates with an automatic temperature control system to ensure efficient and uniform melting.

-

Discharge and Collection: The compacted blocks are discharged from the machine and collected, ready for recycling.

EPS Foam Melting Machine: Efficient Recycling for a Sustainable Future

Advantages of EPS Foam Melting Machines

-

Volume Reduction: Reduces EPS foam volume by up to 90%, lowering storage and transportation costs.

-

Energy Efficiency: Modern machines are environmentally friendly thanks to their energy-saving design.

-

Recycling: Melted foam is converted into reusable materials, creating economic value.

-

Environmental Impact: Recycling EPS waste reduces environmental pollution and contributes to a more sustainable future.

What to Consider When Choosing an EPS Melting Machine

-

Capacity: Choose a machine with a production capacity that matches your business needs.

-

Energy Consumption: Energy-efficient models help reduce long-term operational costs.

-

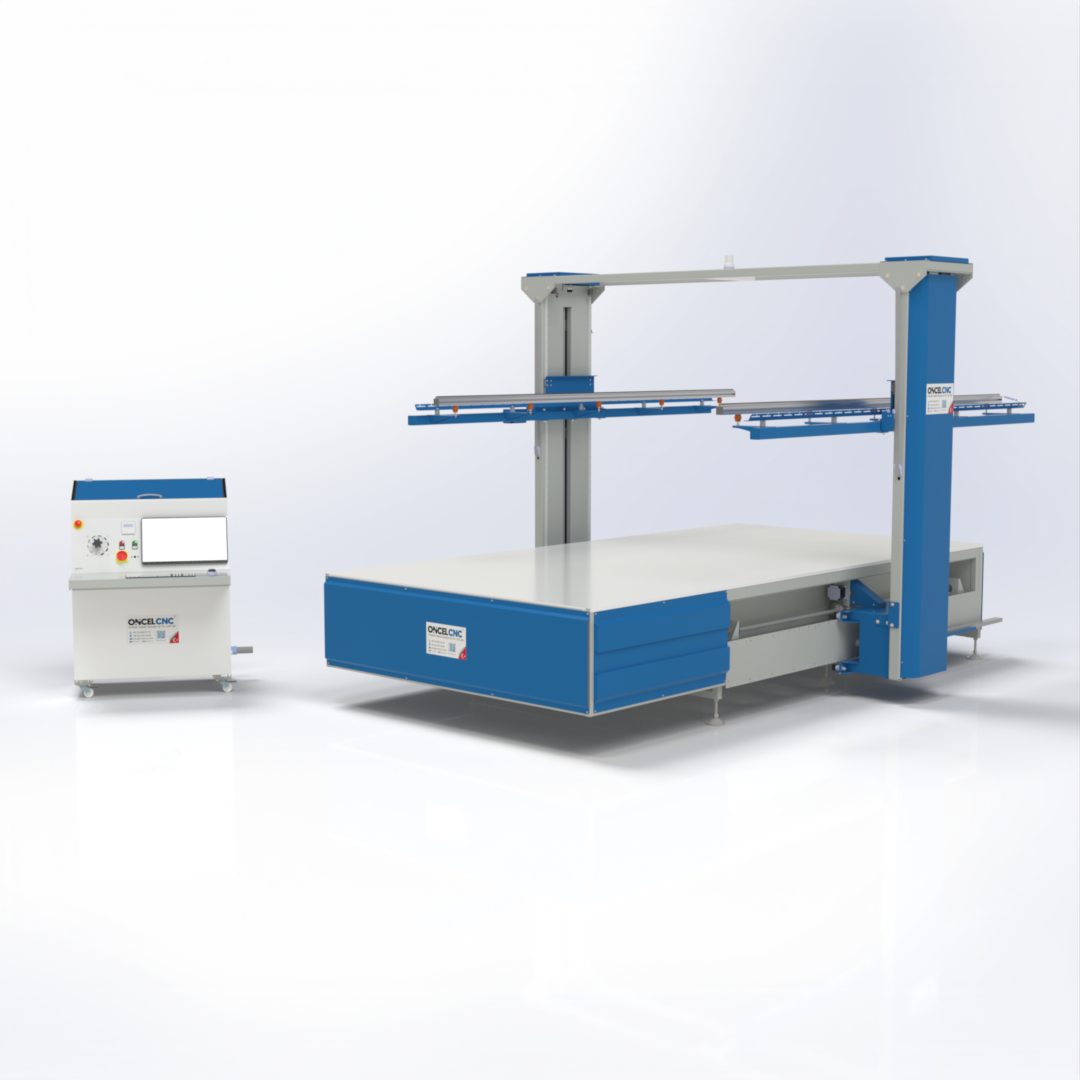

Size and Design: Select a machine that fits your facility space and has an ergonomic design.

-

Maintenance and Support: Opt for a brand that offers easy maintenance and reliable service support.

Why Choose ÖNCEL CNC?

With the ÖNCEL CNC EPS/XPS/Styrofoam Melting Machine, you can not only dispose of your foam waste effectively but also generate additional income through recycling. It’s a complete solution for businesses looking to turn waste into value.