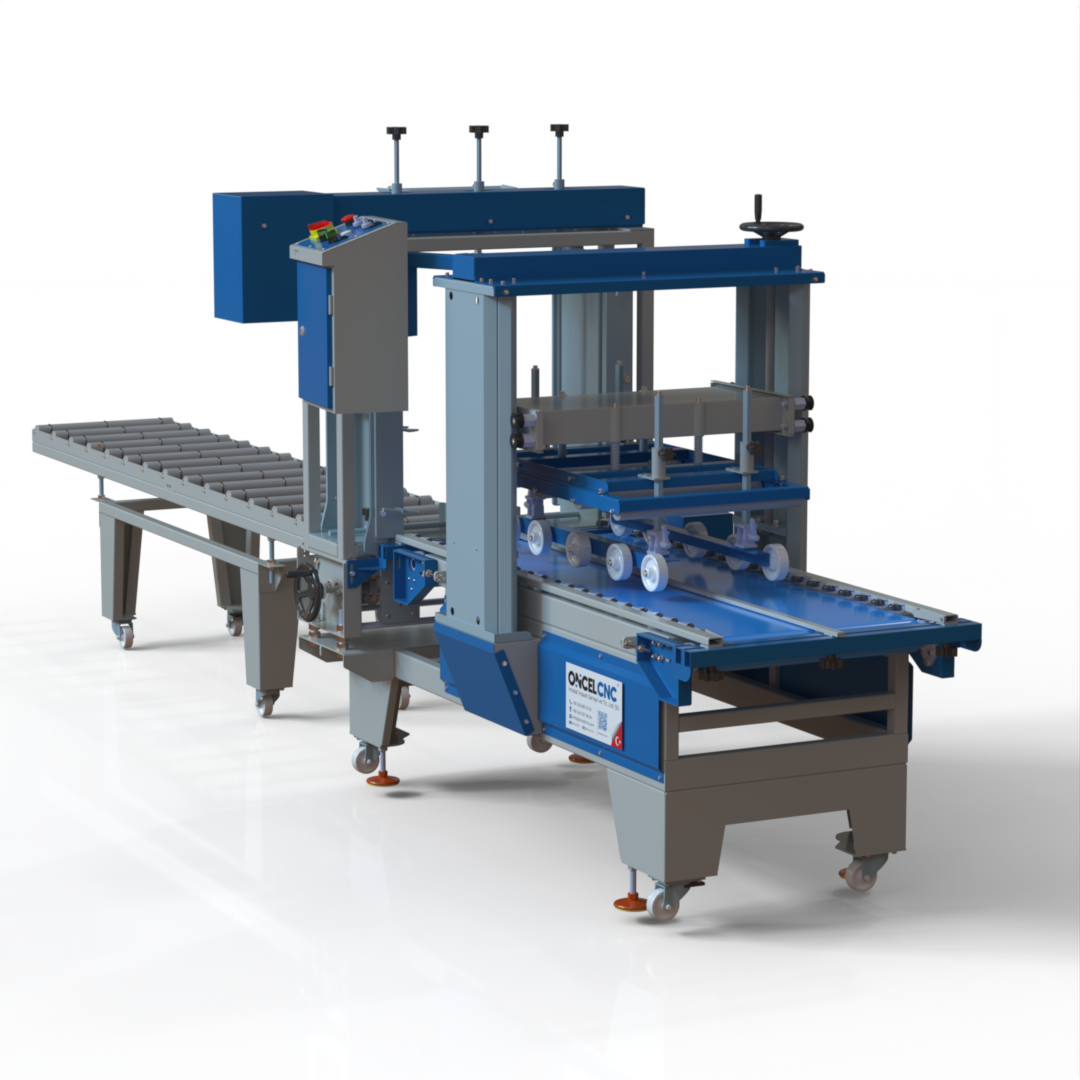

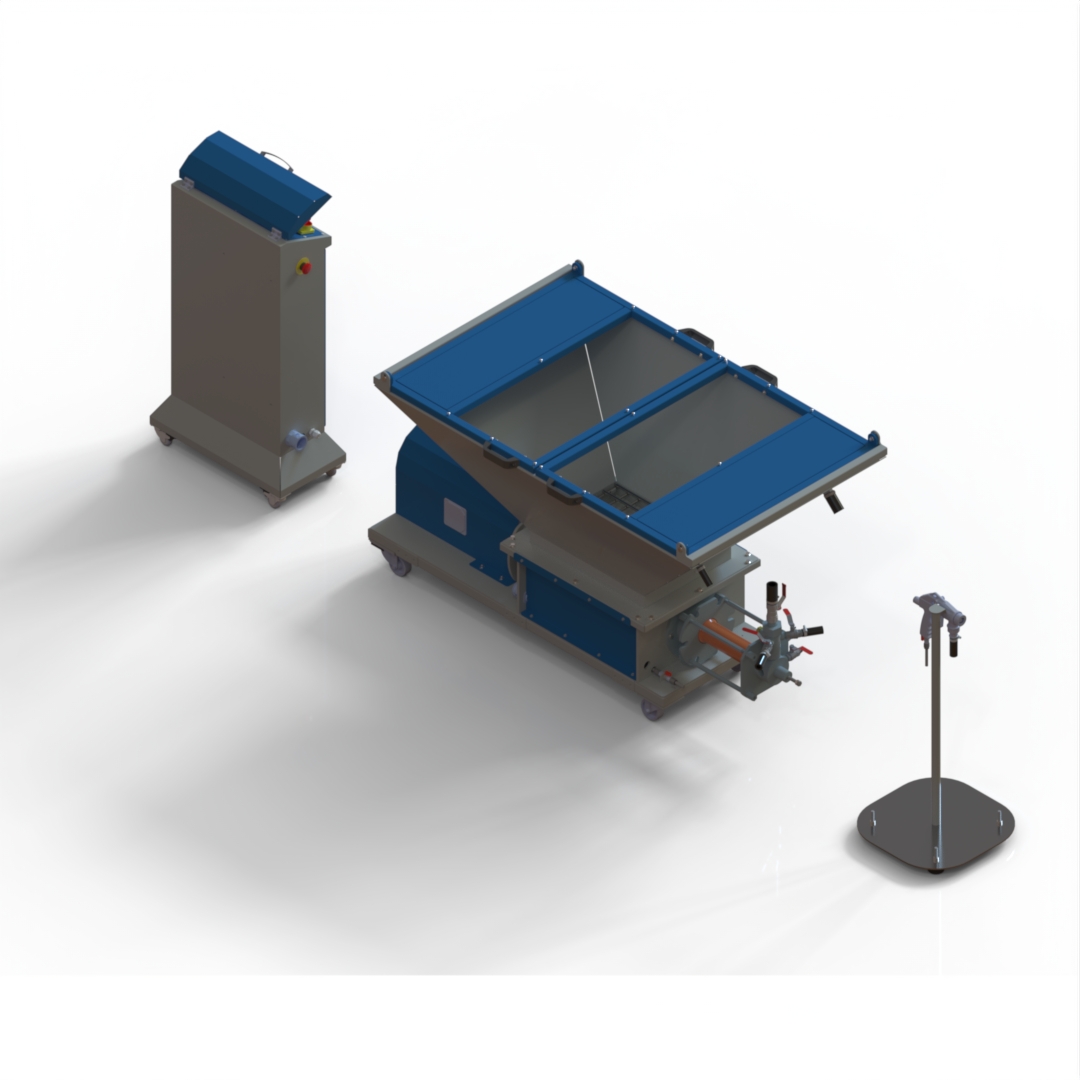

Our website receives a lot of traffic with the words and our customers in Türkiye can mostly reach us from the words “söve makine, söve makinesı, styrofoam cutting, söve kesme, cnc söve kesme makina, cnc söve kesme makina, eps styrofoam pattern printing machine, söve levhaları machine, eps styrofoam crushing machine, söve mortar mixing machine, söve mortar spraying” while our customers in Europe can reach us from the words “jamb machine, jamb machine, styrofoam cutting, jamb cutting, cnc jamb cutting machine, cnc styrofoam cutting machine, eps styrofoam pattern printing machine, jamb coating machine, eps styrofoam crushing machine, jamb mortar mixing machine, jamb mortar spraying, söve makinesi, söve makinası, strafor kesim, söve kesim, cnc söve kesim makinesi, cnc stropiyer kesim makinesi, eps strafor desen baskı makinesi, söve kaplama makinesi, eps strafor kırma makinesi, söve harcı karıştırma makinesi, söve harcı püskürtme,jamb machine, jamb machine,OTOMATİK HARÇ KARIŞTIRICI,AUTOMATIC MORTAR MIXER,AUTOMATIC MORTAR MIXING MACHINE, HARÇ KARIŞTIRMA MAKİNESİ, CEMENT MIXING MACHINE, styrofoam cutting, jamb cutting, cnc jamb cutting machine, cnc styrofoam cutting machine, eps styrofoam pattern printing machine, jamb coating machine, eps styrofoam crushing machine, jamb mortar mixing machine, jamb mortar spraying ,Hot Wire,Cnc,Foam,Sytrofoam,Foam Cutting, Cnc Polystyrene cutting machine,Hot Wire Polystyrene cutting machine,Penoplast cutting machine,Penoplast cnc cutting machine Hot Wire,Hot Wire Cnc,Hot Wire Xps,Hot wire Xps cutting machine,Xps Cutting,Xps Cnc Cutting,Polystyrene cutting machine,Sytrofoam cutting, Foam Arch Cutting, Foam arch base cutter, arch base cutting machine,styrofoam cutting machine,arch and base Polystyrene cutting machine,arch and base Penoplast cutting machine Eps Foam Edge Sizing- Foam Edge sizing-Penoplast edge sizing machine- Polystyrene Edge sizing machine-Styrofoam Edge sizing machine-styrofoam edge cutting machine-Foam edge cutting machine-Penoplast Edge Cutting Machine-Polystyrene Edge Cutting Machine

Hot Wire,Cnc,Foam,3 axis Sytrofoam cutting,3 axis Foam Cutting, Cnc Polystyrene cutting machine,Hot Wire Polystyrene cutting machine,Penoplast cutting machine,Penoplast cnc cutting machine, EPS melting machine, Eps foam melting machine, Eps hot melting, foam recycling machine, styrofoam hot melting machine,Styrofoam Densifier Hot Melting Machines,EPS Densifier Hot Melting Machines EPS melting shredder, EPS foam shredder machine, EPS shredder, EPS-XPS recycling machine,XPS shredder machine,4 axis foam router machine,4 axis router machine,4 axis EPS router machine, EPS cnc router machine, EPS router machine, EPS CNC router machine, styrofoam sculpture making machine,styrofoam sculpture machine,3 axis foam router machine,3 axis router machine,3 axis EPS router machine, EPS cnc router machine, EPS router machine, EPS CNC router machine, styrofoam sculpture making machine,styrofoam sculpture machine,AUTOMATIC MORTAR MIXING MACHINE, Mortar mixing machine, automatic jamb mortar mixing machine, jamb mortar mixing machine,styrofoam coating mortar machine,foam coating mortar making machine,Polystyrene coating mortar production machine,automatic penoplast coating mortar making machine ,automatic styrofoam coating mortar making machine ,automatic penoplast coating mortar making machine ,penoplast coating mortar machine,Polystyrene coating mortar machine, MORTAR MIXING MACHINE, Mortar mixing machine, jamb mortar mixing machine, jamb mortar mixing machine,styrofoam coating mortar machine,foam coating mortar making machine,Polystyrene coating mortar production machine, penoplast coating mortar making machine , styrofoam coating mortar making machine , penoplast coating mortar making machine ,penoplast coating mortar machine,Polystyrene coating mortar machine,Hot Eps Foam Shape Press,PANEL EMBOSSING THERMOPRESS MACHINE,foam press machine,eps styrofoam termoforming machine,FOAM HOT STAMP PRESS MACHINE,eps styrofoam forming machine,eps styrofoam shaper printing machine,Styrofoam wall panels,Styrofoam wall panels for indoors or outdoors, EPS coating machine,Foam Coating Machine,AUTOMATIC FOAM COATER,Polystyrene Coating Machine,Penoplast Coating Machine,Styrofoam Coating Machine,AUTOMATIC MORTAR COATING MACHINE,FOAM MORTAR COATING MACHINE,Eps Foam Coating Machine, Fully Automatic Mortar Spraying Machine,Automatic Spray Coating Machine,Mortar spraying machine,automatic acrylic spraying machine,acrylic spraying machine,Automatic mortar coating machine,Mortar Spraying Machine,semi-Automatic Spray Coating Machine,Mortar spraying machine, acrylic spraying machine,acrylic spraying machine,manuel mortar coating machine with spray gun, spray coating machine,moulding, crown molding, molding, crown moulding,CNC strafor kesim makinesi,strafor kesme makinası,CNC EPS kesim makinesi,CNC stropiyer kesim makinası,strafor desen kesme makinesi,EPS strafor kesme makinesi,CNC söve profil kesim makinesi,strafor panel kesim makinesi,CNC dekoratif strafor kesim,3 eksen strafor kesim makinesi,4 eksen strafor kesim makinesi,CNC strafor şekillendirme makinesi,strafor kavis kesim makinesi,CNC EPS profil kesim makinesi,strafor kenar düzeltme makinesi,sıcak tel strafor kesim makinesi,CNC sıcak tel kesim makinesi,sıcak tel EPS kesim makinesi,sıcak tel XPS kesim makinesi,strafor sıcak tel kesim makinası,CNC sıcak tel söve kesim,XPS sıcak tel kesim makinesi,sıcak tel dekoratif kesim makinesi,strafor kemer kesim makinesi,CNC sıcak tel profil kesim,strafor oyma makinesi,CNC strafor oyma makinesi,EPS desen oyma makinesi,strafor 3D kesim makinesi,CNC strafor kemer kesim makinesi,strafor kenar kesim makinesi,EPS panel kesim makinesi,strafor blok kesme makinesi,CNC strafor detay kesim makinesi,strafor hassas kesim makinesi,CNC foam cutting machine,CNC polystyrene cutting machine,CNC EPS cutting machine,CNC styrofoam profiling machine,foam contour cutting machine,3-axis CNC foam cutting machine,4-axis CNC foam cutting machine,CNC decorative foam cutting,styrofoam panel cutting machine,CNC foam shaping machine,EPS contour cutting machine,foam edge trimming machine,CNC foam profile cutting machine,polystyrene precision cutting machine,hot wire foam cutting machine,CNC hot wire cutting machine,hot wire EPS cutting machine,hot wire XPS cutting machine,styrofoam hot wire cutting machine,CNC hot wire jamb cutting,hot wire decorative foam cutting,foam arch cutting machine,hot wire polystyrene cutting machine,CNC hot wire profile cutting,foam carving machine,CNC foam carving machine,EPS pattern carving machine,styrofoam 3D cutting machine,CNC foam arch cutting machine,foam edge cutting machine,EPS panel cutting machine,styrofoam block cutting machine,CNC foam detail cutting machine,polystyrene precision cutting machine,EPS eritme makinesi,strafor eritme makinesi,XPS geri dönüşüm makinesi,strafor kırma ve eritme makinesi,EPS strafor geri dönüşüm makinesi,strafor yoğunlaştırma makinesi,EPS sıcak eritme makinesi,strafor geri dönüşüm makinası,CNC strafor geri dönüşüm makinesi,EPS yoğunlaştırma makinesi,foam recycling machine,styrofoam densifier machine,EPS hot melting machine,polystyrene recycling machine,CNC foam recycling machine,EPS shredder machine,styrofoam melting machine,foam densifier machine,CNC EPS shredder,polystyrene hot melting machine,CNC söve kaplama makinesi,strafor kaplama makinası,EPS kaplama makinesi,otomatik strafor kaplama makinesi,söve harcı kaplama makinesi,CNC strafor harcı püskürtme makinesi,otomatik harç püskürtme makinesi,strafor yüzey kaplama makinesi,EPS dekoratif kaplama makinesi,strafor panel kaplama makinesi,automatic foam coating machine,styrofoam coating machine,CNC foam coating machine,EPS coating machine,polystyrene coating machine,automatic mortar spraying machine,foam mortar coating machine,CNC mortar spraying machine,decorative foam coating machine,styrofoam surface coating machine,çimento kaplama makinesi,otomatik çimento kaplama makinesi,strafor çimento kaplama makinesi,söve çimento püskürtme makinesi,CNC çimento kaplama makinesi,çimento harcı karıştırma makinesi,otomatik çimento harcı makinesi,strafor çimento harcı üretim makinesi,EPS çimento kaplama makinesi,cement coating machine,automatic cement coating machine,styrofoam cement coating machine,cement mortar spraying machine,CNC cement coating machine,cement mortar mixing machine,automatic cement mortar machine,polystyrene cement coating machine,foam cement coating machine,çimento sıva makinesi,strafor sıva kaplama makinesi,otomatik sıva püskürtme makinesi,CNC sıva kaplama makinesi,cement plaster coating machine,automatic cement plaster spraying machine,styrofoam cement plaster coating machine,CNC cement plaster coating machine,çimento harcı püskürtme makinesi,otomatik çimento harcı püskürtme makinesi,strafor çimento sıva makinesi,EPS çimento sıva makinesi,cement mortar spraying machine,automatic cement mortar spraying machine,polystyrene cement plaster machine,foam cement plaster machine,CNC söve harcı karıştırma makinesi,otomatik harç karıştırma makinesi,strafor kaplama harcı makinesi,EPS harcı karıştırma makinesi,söve harcı üretim makinesi,strafor harcı karıştırma makinası,otomatik söve harcı makinesi,CNC harç üretim makinesi,foam mortar mixing machine,automatic mortar mixing machine,styrofoam coating mortar machine,polystyrene mortar production machine,CNC mortar mixing machine,jamb mortar production machine,automatic foam mortar machine,EPS termoform makinesi,strafor şekillendirme makinesi,CNC strafor baskı makinesi,EPS sıcak baskı makinesi,strafor panel şekillendirme makinesi,otomatik EPS şekillendirme makinesi,strafor dekoratif baskı makinesi,EPS foam thermoforming machine,styrofoam shaping machine,CNC foam stamping machine,hot press foam machine,automatic EPS forming machine,decorative styrofoam press machine,foam panel shaping machine