Styrofoam crown moulding machines are specialized equipment designed to produce decorative ceiling and wall mouldings (cornices) from polystyrene foam (styrofoam). These machines are widely used in the interior decoration industry due to styrofoam‘s lightweight, cost-effective, and aesthetically pleasing properties compared to materials like wood or MDF.

Features of Styrofoam Crown Moulding Machines

-

Precision Cutting and Shaping: The malleable nature of styrofoam allows these machines to create intricate designs with high accuracy.

-

Hot Wire Cutting Technology: Most styrofoam moulding machines utilize hot wire or CNC-controlled cutting systems for precision.

-

Fast Production: Automated feeding and cutting systems enable high-volume production in a short time.

-

Customization: Adjustable moulds allow for the creation of various profiles and designs.

Advantages

-

Lightweight: Styrofoam mouldings are easy to install and do not add significant weight to structures.

-

Cost-Effective: They are more affordable compared to materials like wood or aluminum.

-

Aesthetic Versatility: The paintable surface allows customization with different colors and textures.

-

Insulation Properties: Styrofoam provides thermal and acoustic insulation benefits.

Applications

Styrofoam mouldings are used in a wide range of settings, from homes and hotels to offices and restaurants. They serve as an aesthetic complement in both modern and classic interior designs.

Öncel CNC Styrofoam Crown Moulding Machines

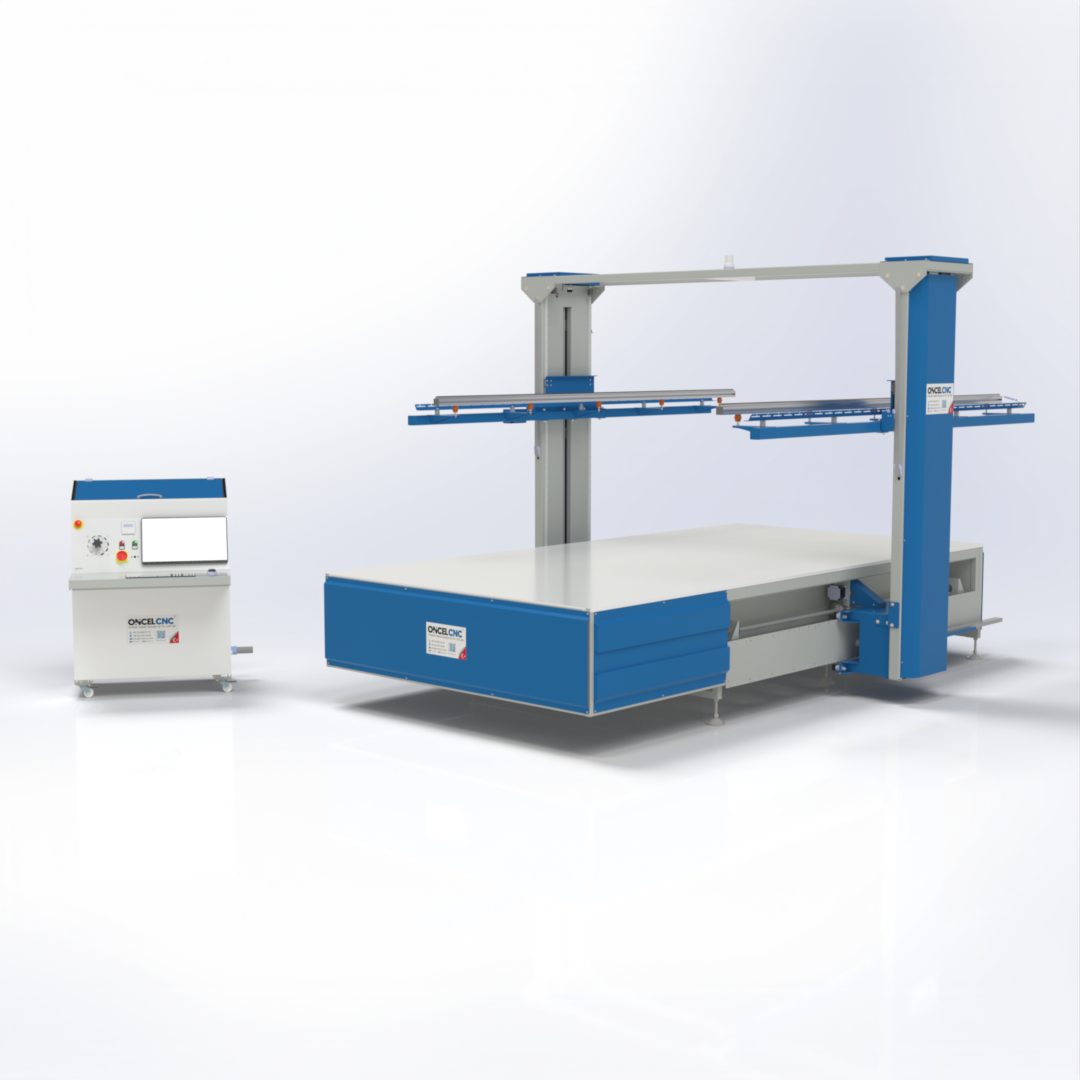

Öncel CNC, a Türkiye-based manufacturer, is renowned for its high-tech CNC machines designed for producing decorative ceiling and wall mouldings from styrofoam (EPS and XPS). These machines excel in the construction, decoration, advertising, and packaging industries, utilizing hot wire CNC foam cutting technology to create lightweight and aesthetic crown mouldings.

Features and Benefits:

-

Hot Wire Cutting Technology: Öncel CNC’s machines use a heated wire system to precisely and cleanly cut styrofoam, enabling the creation of intricate patterns and 3D shapes with ease.

-

3D Rotary Table Module: The 3D styrofoam cutting machine is equipped with a rotary table module, allowing the production of complex designs such as polygonal, twisted, or inclined mouldings, enhancing design versatility.

-

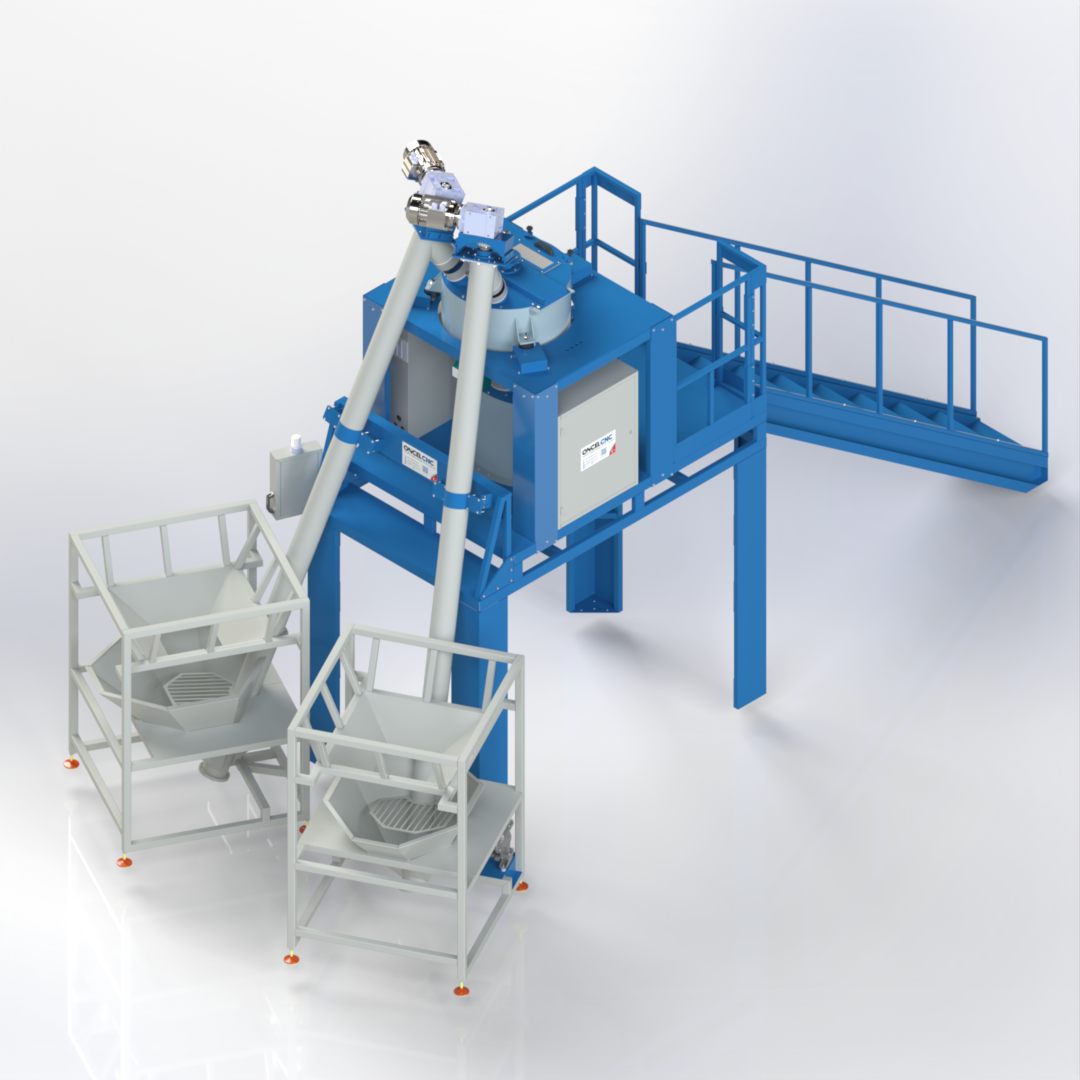

Automatic Söve Coating Machine: This machine applies homogeneous plaster to cut styrofoam products, capable of coating mouldings and claddings ranging from 30-560 mm in width. It offers easy assembly and cleaning.

-

Pattern Printing Machine: Used to imprint decorative patterns like wood, stone, or brick textures onto styrofoam mouldings. Aluminum moulds with Teflon coating prevent sticking and ensure durability.

-

Energy Efficiency and Low Maintenance: Öncel CNC machines are designed for high energy efficiency and require minimal maintenance due to their robust construction. Regular cleaning and periodic inspections ensure long-term performance.

köpük strafor söve makinesi crown moulding moulding machines Full Automatic Mortar Spray Coating machine

Conclusion

Styrofoam crown moulding machines offer a cost-effective and aesthetic solution for the interior decoration industry. The lightweight, durable, and easily processed styrofoam material is quickly shaped by these machines, making a significant impact in decorative applications.