CNC (Computer Numerical Control) cutting machines are revolutionizing the way styrofoam is utilized in various industries by offering precise and personalized cutting capabilities. Whether you’re working on architectural models, theatrical sets, packaging, or art projects, CNC machines provide the flexibility to create intricate and customized designs. Here’s a deeper look into how you can personalize your styrofoam designs using CNC cutting technology:

Understanding CNC Cutting Technology

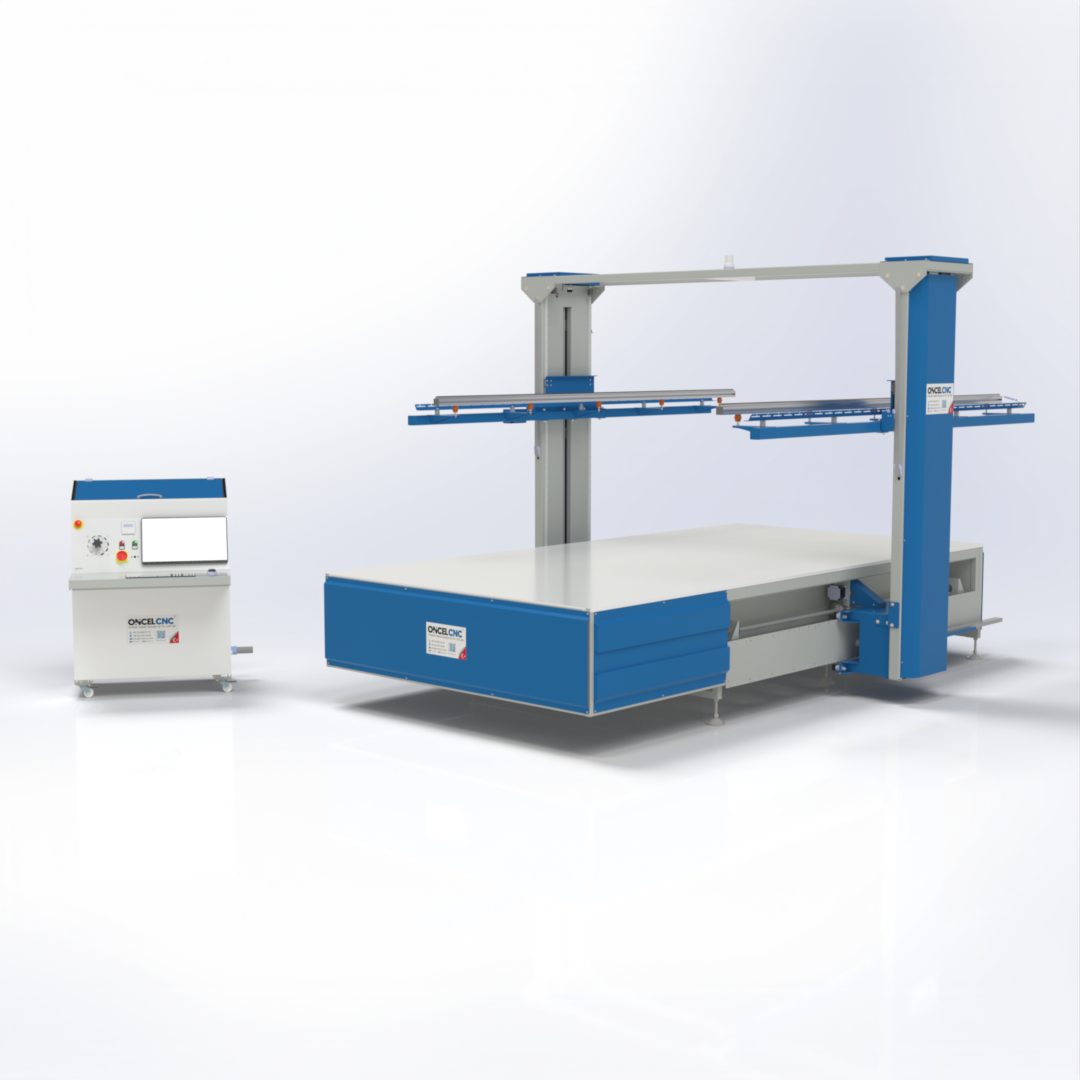

CNC cutting machines work by translating digital designs into physical forms through precise cutting paths controlled by computer software. These machines can handle various materials, including styrofoam, a popular choice due to its light weight and ease of molding. CNC routers, for example, can sculpt, engrave, and shape styrofoam with high precision to produce detailed and complex designs that are difficult to achieve manually.

Step-by-Step Guide to Personalizing Styrofoam Designs

- Design Conceptualization:

- Start with a clear vision of what you want to create. Use design software like AutoCAD, SolidWorks, or Adobe Illustrator to sketch out your idea. These programs can generate the necessary digital files that CNC machines can read, such as DXF or SVG files.

- Machine Setup:

- Choose the right CNC machine for your project. For styrofoam, a CNC router or a laser cutter is often preferred due to their ability to handle soft materials without causing damage.

- Set up the machine according to the material’s specifications. This includes adjusting the cutting speed, feed rate, and depth to ensure clean cuts and minimize waste.

- Material Preparation:

- Secure the styrofoam block onto the machine bed. Ensure it is stable to avoid any movement during the cutting process, as this could affect the precision of the design.

- Cutting Process:

- Upload your design file into the CNC machine’s software. This software directs the machine’s cutter to follow the exact paths outlined in your design.

- Monitor the cutting process to ensure everything runs smoothly. CNC machines are generally automated, but it’s important to watch for any potential issues that may arise.

- Post-Processing:

- Once the cutting is complete, remove the styrofoam piece from the machine. You may need to perform additional steps like sanding or painting to enhance the appearance and durability of the design.

- If the design requires it, you can assemble multiple pieces to create more complex structures.

Tips for Optimizing Your CNC Cutting Projects

- Test Cut: Before executing the final design, make a test cut on a small piece of styrofoam. This helps you verify the settings and adjust them if necessary.

- Tool Choice: Use cutting tools that are specifically designed for styrofoam to prevent tearing or melting the material.

- Regular Maintenance: Keep your CNC machine well-maintained to ensure the highest level of accuracy and safety.

- Safety First: Always adhere to safety protocols while operating CNC machines. Wear protective gear, and ensure the working area is well-ventilated, especially when cutting materials that might emit fumes.

CNC cutting machines offer a unique opportunity to transform simple styrofoam blocks into elaborate, personalized creations. By harnessing the power of digital design and precise cutting technology, you can produce one-of-a-kind items or repetitive patterns with equal ease. Whether for commercial purposes or personal projects, CNC technology pushes the boundaries of what you can achieve with styrofoam, making it an invaluable tool in any creator’s arsenal.