Öncel CNC Styrofoam Cutting Machines: Technology and Superior Features

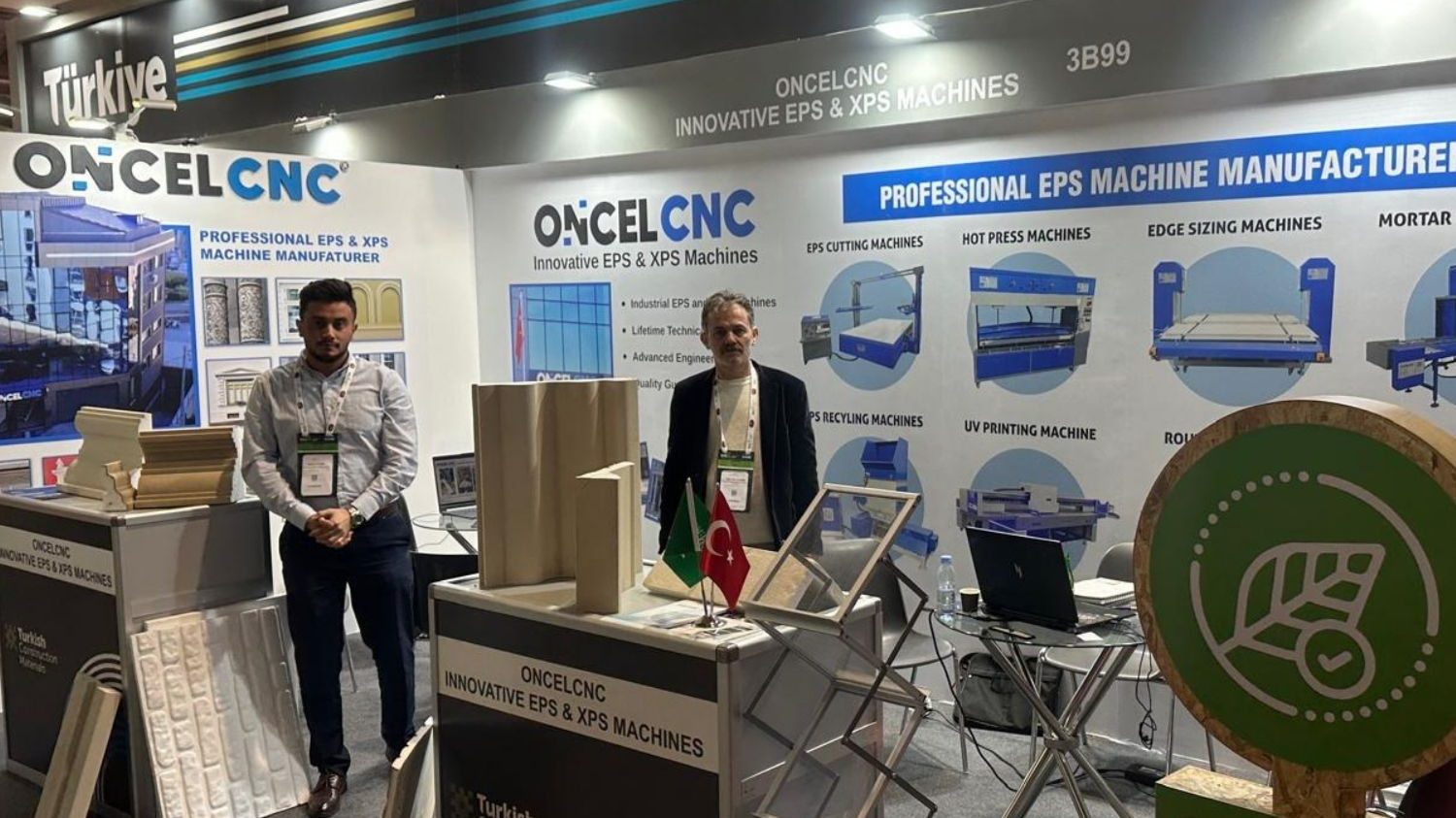

Öncel CNC, a leading Turkish manufacturer, offers advanced hot wire CNC styrofoam cutting machines designed for precision cutting of materials such as Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS). Utilizing titanium wire and computer-controlled systems, these machines create intricate 2D and 3D shapes with exceptional accuracy. This SEO-optimized blog post explores the technology, components, applications, and advantages of Öncel CNC styrofoam cutting machines, highlighting their role as a top choice for industries worldwide.

How Öncel CNC Styrofoam Cutting Machines Work

Öncel CNC styrofoam cutting machines operate by heating a titanium wire with an electric current to melt or vaporize styrofoam material. The wire is guided by a CNC system along precise paths defined by G-code. The process involves the following steps:

-

Design Phase: Shapes are designed using CAD software such as Autodesk AutoCAD or CorelDRAW. The design is converted into G-code using CAM software like DevFoam or Mach3.

-

Machine Setup: Parameters such as wire temperature (typically 200–300°C) and cutting speed are adjusted based on the styrofoam’s density and thickness. Öncel CNC’s control system simplifies parameter optimization.

-

Cutting Process: The heated titanium wire is directed along X, Y, and Z axes by stepper motors and a control unit. The machines are equipped with high-precision linear rails for smooth operation.

-

Advanced Features: Öncel CNC machines offer multi-wire cutting for high-volume production and rotary tables for 3D shapes, enabling efficient completion of complex projects.

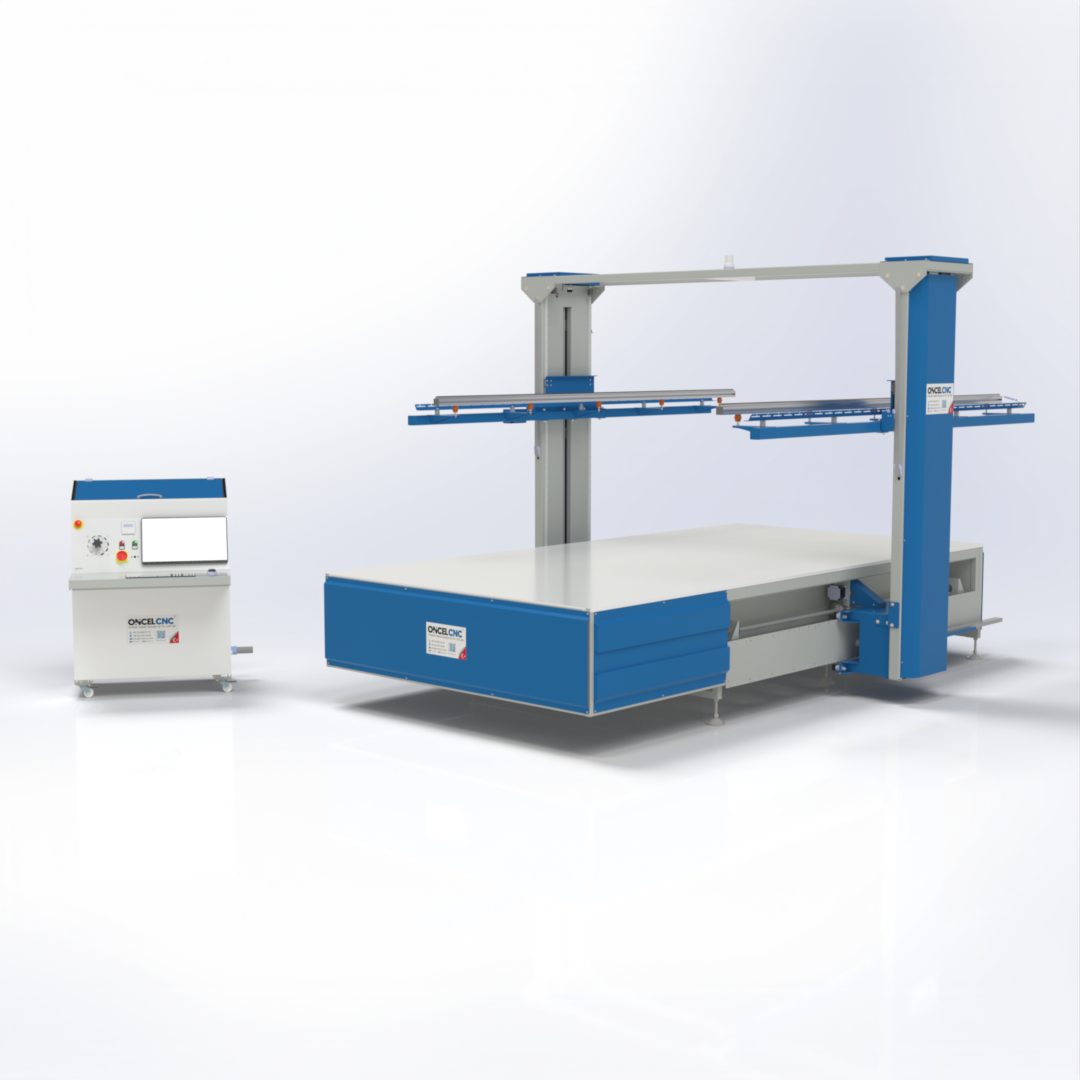

Key Components of Öncel CNC Styrofoam Cutting Machines

Öncel CNC machines are built with high-quality components to ensure durability and precision:

-

Hot Wire System: The titanium wire, heated via a controlled power source, cuts styrofoam with precision. Automatic tension adjustment ensures consistent cutting quality.

-

CNC Control Unit: Interprets G-code to manage wire movements. A user-friendly touchscreen interface allows operators to control the machine effortlessly.

-

Frame and Rails: Constructed from steel or aluminum, the frame ensures stability. Linear rails and bearings enable smooth, precise wire movement, achieving ±0.5 mm accuracy.

-

Worktable: Designed to secure styrofoam blocks, the worktable is customizable to suit various project sizes (e.g., 2m x 1.5m or larger).

-

Software Support: Compatible with industry-standard software like DevFoam, AutoCAD, and Mach3, Öncel CNC machines include preloaded design libraries for quick setup.

Applications of Öncel CNC Styrofoam Cutting Machines

Öncel CNC styrofoam cutting machines serve a wide range of industries in Turkey and globally:

-

Construction: Ideal for producing insulation panels, window sills, cornices, and decorative facade elements, ensuring energy-efficient building materials.

-

Advertising: Creates 3D logos, signage, and exhibition displays. Lightweight styrofoam offers cost-effective solutions for visually striking products.

-

Art and Decoration: Produces complex 3D shapes for interior decor, sculptures, and custom designs, blending aesthetics with functionality.

-

Prototyping: Delivers high-precision cuts for architectural models, RC airplane parts, and industrial prototypes.

-

Packaging: Manufactures custom-shaped styrofoam packaging for enhanced product protection and shipping efficiency.

Advantages of Öncel CNC Styrofoam Cutting Machines

Öncel CNC machines stand out with the following benefits:

-

High Precision: Achieve ±0.5 mm tolerances, ensuring flawless cutting quality for intricate designs.

-

User-Friendly Interface: Touchscreen controls and Turkish-language software support enable quick learning and operation.

-

Made in Turkey: Designed for local market needs, these machines come with fast technical support and service.

-

Durability: Robust frames and high-quality components require minimal maintenance, backed by 1–2 year warranties.

-

Cost-Effective: Competitive pricing caters to small businesses and large manufacturers alike.

Considerations for Optimal Use

To maximize performance, consider the following:

-

Parameter Optimization: Adjust titanium wire temperature and speed based on styrofoam type and thickness. Öncel CNC provides training to streamline this process.

-

Maintenance: Regular checks on the titanium wire maintain cutting quality and extend wire lifespan. Öncel CNC offers prompt spare parts support.

-

Software Proficiency: While user-friendly, CAD/CAM software may require initial training. Öncel CNC’s Turkish-language resources simplify onboarding.

Why Choose Öncel CNC?

Öncel CNC combines the advantages of local production with quality, affordability, and dedicated support. Compared to international competitors, Öncel CNC machines are tailored to Turkey’s construction, advertising, and decoration industries. Priced between approximately $2,000–$15,000, they suit various budgets, with free installation and training enhancing user experience.

Conclusion

Öncel CNC styrofoam cutting machines, powered by titanium wire technology, deliver precise, fast, and versatile cutting solutions.