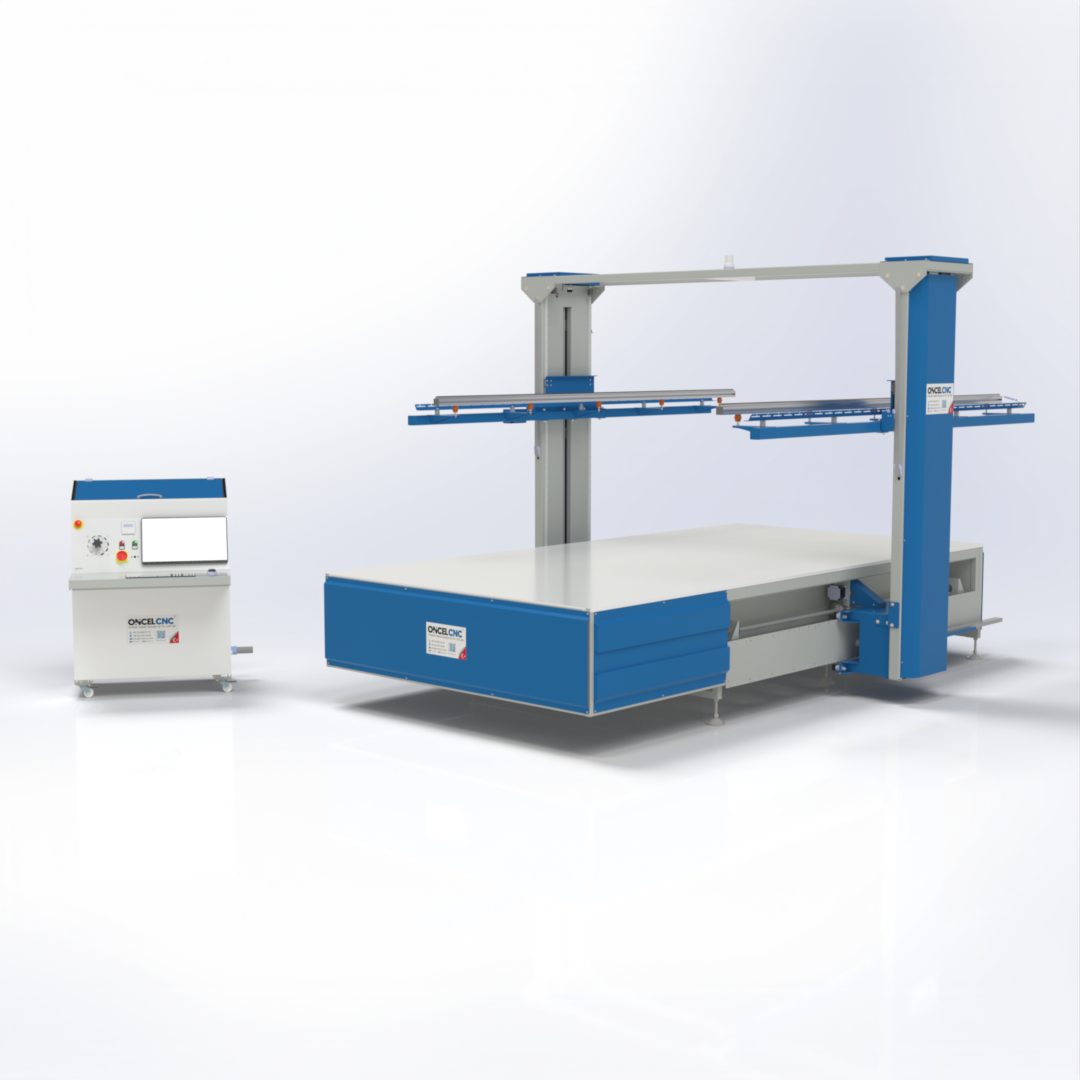

| MAIN MACHINE DIMENSIONS | | 3400 mm x 3100 mm x 2000 mm |

| (Including Working Area) |

| CONTROL UNIT DIMENSIONS | | 810 mm x 950 mm x 1260 mm |

| PROCESSABLE PRODUCT SIZES | | 2780 mm x 2015 mm x 1050 mm |

| CUTTING CAPACITY | | Cutting with 20 Wires Simultaneously |

| BODY STRUCTURE | | Steel Profile, HRP Sheet, 18 mm MDF Panels |

| DRIVE SYSTEM | | Stepper Motors with and without Brake |

| CONTROL SYSTEM | | 2-Axis CNC Control (Mach3 Software) |

| X-AXIS MOTOR | | LeadShine 86CM45C – 4.5 Nm, NEMA34 (No Brake) |

| Y-AXIS MOTOR | | LeadShine 86CM45C-BZ – 4.5 Nm, NEMA34 (With Brake) |

| CUTTING SPEED | | 450 mm/min |

| CUTTING ACCELERATION | | 200 mm/s² |

| BODY COLOR | | Blue (RAL 5015) and Grey (RAL 7035) |

| SAFETY SYSTEMS | | Emergency Stop Button |

| Warning Light and Siren |

| Axis Limit Switches |

| High/Low Voltage, Current, and Load Protection |

| Ground Fault Protection |

| Overload and Power Surge Protection |

| TOTAL ELECTRIC POWER | | Approx. 5 kW — 3P 400 V / 50 Hz |

| WEIGHT | | 1000 kg |

Oncel CNC XPS Hot Wire Cutting Machine: Precision Meets Performance in Extruded Polystyrene!

Do you want flawless, high-speed cutting results on

XPS foam blocks?

The

Oncel CNC XPS Hot Wire Cutting Machine is engineered exclusively for

dense extruded polystyrene (XPS) materials—offering superior

surface finish, cutting accuracy, and consistency compared to conventional EPS systems.

Built for the insulation, construction, and architectural decoration industries, this machine provides perfect smooth edges and precise geometry while maintaining thermal efficiency and minimizing waste.

Why Choose Oncel CNC XPS Cutting Machine?

1. Designed Specifically for XPS Foam

XPS foam has a dense, closed-cell structure that requires fine heat control and mechanical precision. Our machine uses high-stability

stepper motors and optimized

wire temperature regulation to ensure

clean, accurate, and sharp-edged cuts without surface melting or roughness.

2. Industrial-Grade Accuracy and Smooth Finish

The

CNC Mach3 control system synchronizes dual-axis motion for

millimetric precision. The result: smooth surfaces and sharp profiles suitable for architectural façades, insulation panels, or technical foam components.

3. Efficient Production with 20-Wire System

With up to

20 wires cutting simultaneously, production time is significantly reduced while maintaining consistent cut quality. This feature is ideal for large-scale manufacturing of façade panels, thermal insulation boards, and XPS-based decorative components.

4. Reliable, Durable, and Easy to Operate

The steel and MDF composite body minimizes vibration for consistent accuracy. A user-friendly CNC interface and durable stepper motors guarantee long-term stability and easy maintenance.

5. Energy Efficient and Safe

Energy-optimized wire heating and

comprehensive safety systems—including emergency stop, siren alerts, and voltage protection—ensure stable, secure operation.

6. Perfect for Insulation and Architecture

From thermal insulation boards to exterior decoration elements, the XPS CNC cutter handles every application with unmatched precision and efficiency.

Applications

- Thermal Insulation Panels: Ideal for high-density extruded polystyrene sheets.

- Architectural Components: Façade profiles, moldings, and decorative wall elements.

- Industrial Prototyping: Dense foam modeling for design and production testing.

- Packaging and Structural Foam: Precision-cut protective and industrial foam products.

Advantages

- Optimized for XPS: Controlled wire temperature ensures perfect surfaces on dense material.

- High Productivity: 20-wire simultaneous cutting boosts output efficiency.

- Stable Operation: CNC-controlled movement prevents wire vibration or cut deviation.

- Low Maintenance: Durable mechanical structure and robust drive system minimize downtime.

- Energy Saving: Efficient heating and drive control reduce overall power consumption.

Technical Highlights

- 2-Axis CNC Mach3 system with high-precision motion control

- Optional 3rd-axis rotary table for 3D contour cutting

- Wire temperature control optimized for XPS foam density

- Integrated safety and power management systems

Take the Lead in XPS Foam Production!

With

Oncel CNC’s precision XPS cutting technology, achieve the

smoothest cuts, fastest turnaround, and

most consistent results in your industry.

Perfect for manufacturers seeking

energy efficiency, accuracy, and long-term reliability.

Key Advantages for XPS Cutting

Precision Control: Dual-axis CNC movement ensures accurate geometrical shapes for architectural or industrial applications.

Simultaneous Multi-Wire Cutting: Up to 20 wires operating at once for increased productivity.

Robust Frame Design: The steel and MDF composite body reduces vibration and maintains long-term accuracy.

Enhanced Safety: Built-in protection systems prevent electrical faults, overheating, and operator hazards.

Optimized for XPS: Calibrated wire temperature control prevents excessive melting and surface deformation typical of dense XPS materials.

User-Friendly Control: Mach3 software enables intuitive operation, wire heat adjustment, and motion monitoring.

Typical Applications

Thermal insulation panel production

Architectural façades and decorative moldings

Industrial and packaging foam components

Custom prototyping and modeling

Summary

The CT.XCN2.V01 CNC XPS Cutting Machine delivers precise, repeatable results in continuous production environments. It is engineered for accuracy, durability, and operator safety, offering a balance between industrial performance and energy efficiency.